Beyond carbon

A successful climate transition depends not only on clean energy, but also on resilient and ethical supply chains. As climate change accelerates, supply networks are increasingly exposed to both environmental and social risks. Extreme weather has disrupted factories and transport routes. Meanwhile, the clean energy boom depends on materials like lithium, cobalt, and copper - often sourced from regions with weak environmental and labour protections.

This convergence of environmental volatility and social fragility introduces significant business risks. Disruptions or unethical practices can cause operational setbacks, regulatory scrutiny, and reputational harm. Companies across sectors have learned that supplier behaviour directly reflects on the brand. Transparency, resilience, and responsible sourcing are no longer optional, but strategic priorities.

Why companies struggle to act

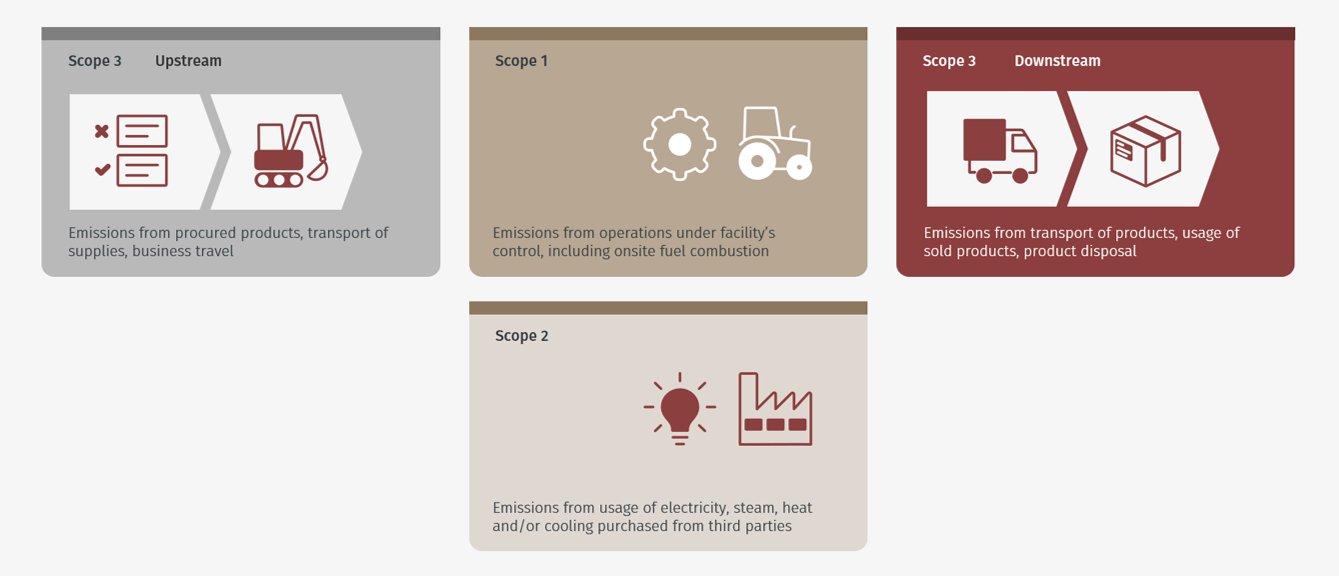

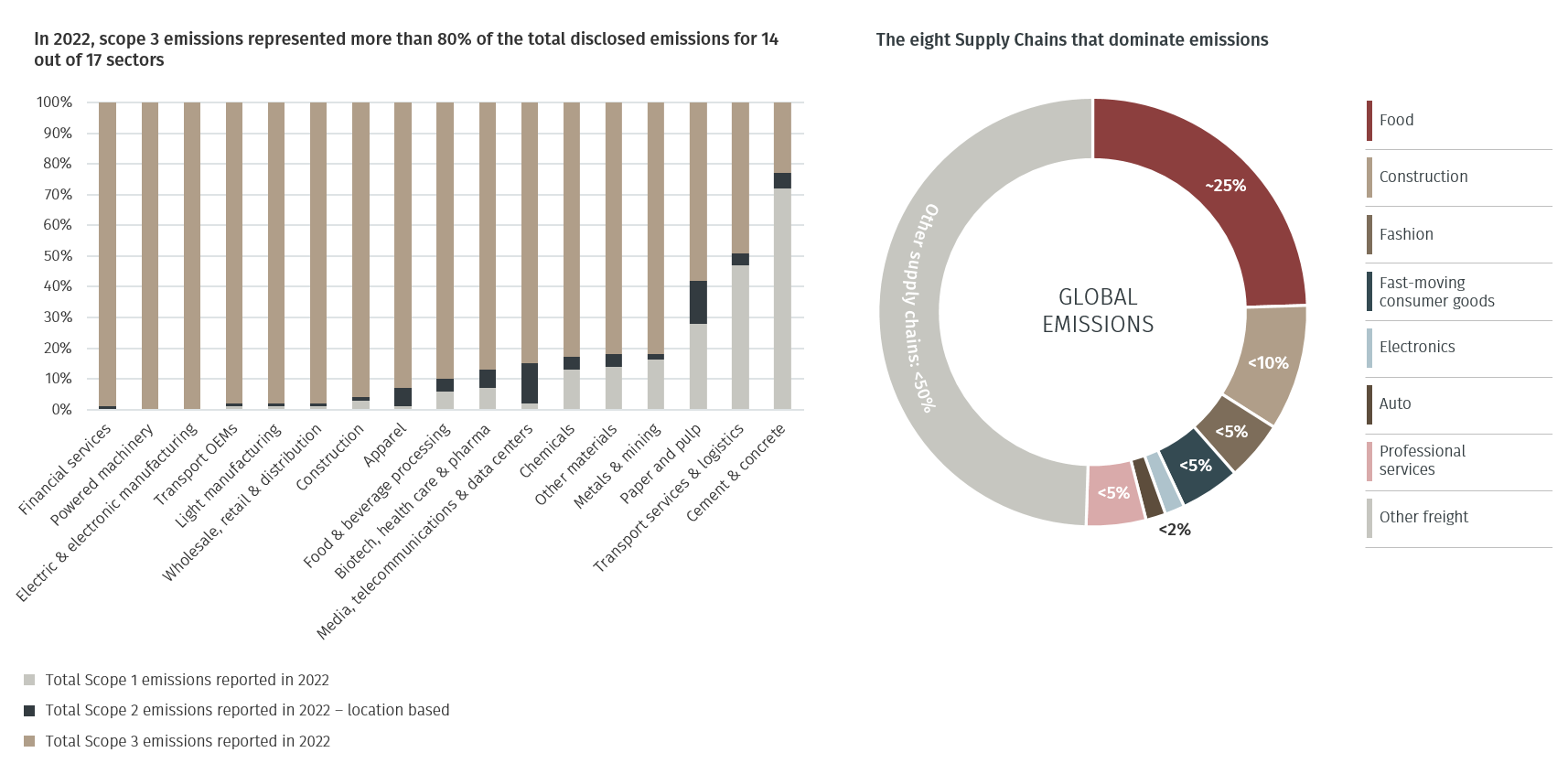

Despite rising awareness, only 24% of companies disclose Scope 3 emissions.3 Measuring and managing these emissions remains difficult due to poor visibility beyond first-tier suppliers and unclear ownership across value chains.

Internal misalignment adds to the challenge. Sustainability teams are often under-resourced, while procurement is driven by cost and delivery targets - not environmental outcomes. This weakens the ability to drive emissions reduction across the chain.

Data quality is another barrier. Many companies rely on industry averages rather than verified supplier data, limiting the credibility of their reporting. Smaller suppliers often lack the tools or funding to measure and report emissions.

Fragmented global regulations further complicate disclosure. Suppliers operate across jurisdictions with differing standards, making coordination difficult. Some firms even avoid Scope 3 reporting to steer clear of scrutiny over high emissions or data gaps.

Turning risk into opportunity

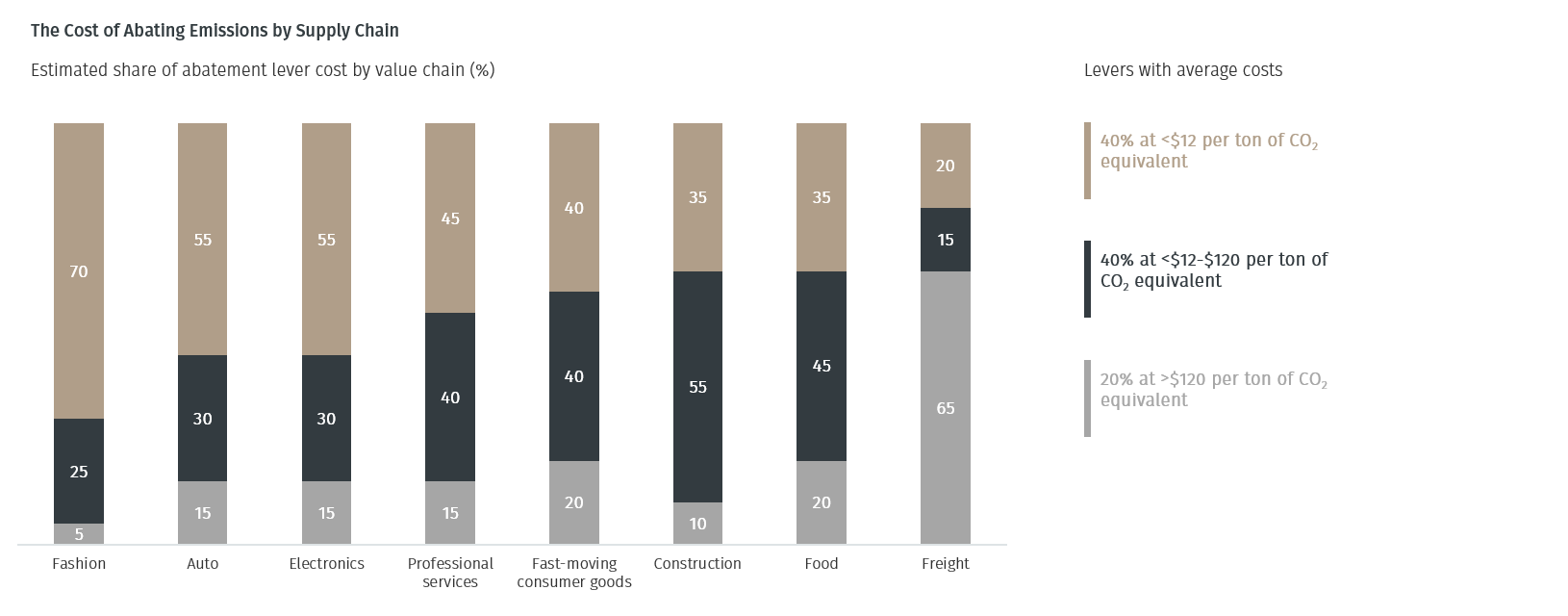

BCG estimates that up to 80% of supply chain emissions can be mitigated with technologies already on the market.4 Yet many of these solutions remain underused due to operational or cultural barriers.

Leading companies are turning supply-chain risks into strategic advantages. They redesign products using recycled or lower-carbon materials, improve packaging and logistics, and work closely with suppliers to reduce emissions. Some co-invest in clean technologies or require key suppliers to set climate targets.

Digital tools are accelerating action. AI-powered platforms enable real-time emissions tracking, while supplier scoring and emissions calculators help companies assess maturity, prioritize support, and track improvements across their value chain.